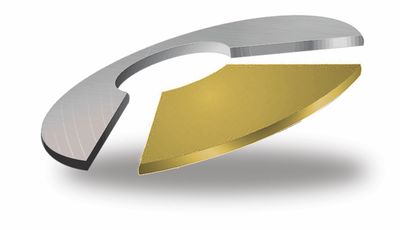

Brass Barrel Nut for MAX & Pico2

This part is a sacrificial part replacement for the brass cylinder (Barrel Nut) in the build platform arm assembly that holds your build platform on your Asiga Pico2 or MAX series 3D Printer. This part is responsible for the tension that keeps your build platform from moving in any direction during separation from the build tray. This part can also be responsible for many approach fail errors if it is getting worn.

Over time or with many calibrations, the threads in this brass cylinder will start to distort. That is what a brass sacrificial part is supposed to do so so as not to allow damage to your machine. This problem does not seem to have been recognized or identified by Asiga so we are identifying it and offering the solution.

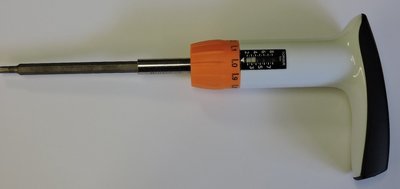

As the threads inside the brass part become worn, your torque wrench will indicate that the stainless screw that goes into this brass cylinder has reached the proper torque setting and your platform should be secure. You then send the build platform to the "Home" position and start your next build only to get an approach fail error on the second or third layer if you make it that far. During your next Zero Calibration procedure, when your build platform has reached the "Home" position, you should test to see if it has any play. If so, then you may need a replacement barrel nut. If you don't already have one, we recommend that you also get one of our calibrated torque wrenches for precision tightening of this screw. We suggest 3 Newton Meters for Pico2, MAX Mini, and MAX-X Series machines. We suggest 3.25 Newton Meters for MAX series machines due to the larger build platform area of this 62um machine.