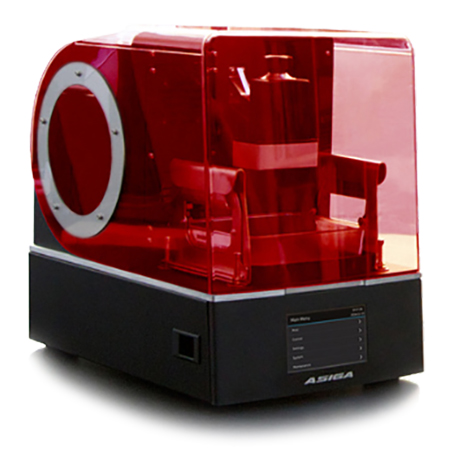

Pico2 Additive

Manufacturing Systems

The PICO2™ is a high power, compact 3D printer for direct manufacturing of quadrant dental models and crown & bridge casting patterns. A small footprint makes the PICO2™ ideal for both the dental lab and clinic. The PICO2™ series is available in two different configurations depending on resolution and build size required. Both models benefit from Asiga’s Slide-And-Separate™ technology for maximizing precision and build speed.

Simple & Fast

Material Changeover

The fastest material change over than any other product on the market. Complete in under 30 seconds.

- Squeeze Build Tray handles to release tray & remove.

- Insert new tray & clamp.

- Done. Start print job.

| Model |  |

UV |

|

UV |

||||

|---|---|---|---|---|---|---|---|---|

| Build Size X, Y, Z | 51 × 32 × 76 mm | 51 × 32 × 76 mm | 64 × 40 × 76 mm | 64 × 40 × 76 mm | ||||

| Pixel Size X, Y | 39 µm | 39 µm | 50 µm | 50 µm | ||||

| Print Speed | 40 mm/h | 40 mm/h | 40 mm/h | 40 mm/h | ||||

| Z Control | 1 µm | 1 µm | 1 µm | 1 µm | ||||

| Light Source | 405 nm UV LED | 385 nm UV LED | 405 nm UV LED | 385 nm UV LED | ||||

| Material System | Open | Open | Open | Open | ||||

| File Inputs | STL, SLC & Stomp | STL, SLC & Stomp | STL, SLC & Stomp | STL, SLC & Stomp | ||||

| Software | Asiga Composer included | Asiga Composer included | Asiga Composer included | Asiga Composer included | ||||

| Network Compatibility | Wifi & Ethernet | Wifi & Ethernet | Wifi & Ethernet | Wifi & Ethernet | ||||

| Industry Sectors | Dental, Jewelry, Audiology | Dental, Audiology, Lab | Dental, Jewelry, Audiology | Dental, Audiology, Lab | ||||

| System Size | 26 × 38 × 37 cm | 26 × 38 × 37 cm | 26 × 38 × 37 cm | 26 × 38 × 37 cm | ||||

| System Weight | 14 kg | 14 kg | 14 kg | 14 kg | ||||

| Packaged Size | 46 × 56 × 50 cm | 46 × 56 × 50 cm | 46 × 56 × 50 cm | 46 × 56 × 50 cm | ||||

| Power | 12 VDC 10A | 12 VDC 10A | 12 VDC 10A | 12 VDC 10A |

Wifi and Ethernet ready

Wifi and ethernet connectivity for seamless workspace integration.

Touch Screen Display

Greater user convenience in the form of a touch screen display with real-time print progress indicators visible on screen.

Open Material System

Print with any suitable material from any material manufacturer. Your choice, no strings.

Asiga’s revolutionary SAS™ process achieves the lowest fabrication forces of any upside-down stereolithography system, resulting in minimal support structures and extraordinary accuracy.