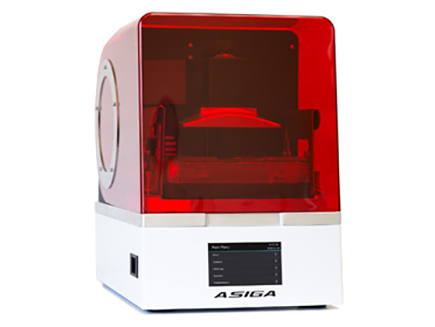

Asiga MAX

Additive Manufacturing System

The Asiga MAX is the world’s most advanced lab 3D printer offering exceptional productivity in a small footprint.

Featuring the cutting-edge Smart Positioning System and 62μm HD print precision, the Asiga MAX is optimized for a variety of precision uses in dental and audiology lab production, engineering prototyping, and other small part manufacturing where precision is essential.

The Asiga Max machines feature an INTERNAL RADIOMETER for ultra-precise LED calibration…a feature not present in any other 3D printer.

Trusted by Audiology & Dental labs across the world.

SPS™ Smart-Positioning-System Technology

Asiga’s unique SPS™ process guarantees every model layer is formed accurately in minimal time, making the MAX ideal for medical device manufacturing where precision is critical.

OPEN MATERIAL SYSTEMS

Print on our machines with any suitable material from any material manufacturer. Your choice, no strings!

Fastest Material Changeover

The fastest material change over than any other product on the market. Complete in under 30 seconds.

| Model | UV |

|||

|---|---|---|---|---|

| Build Size X, Y, Z | 119 × 67 × 75 mm | 119 × 67 × 75 mm | ||

| Pixel Size X, Y | 62 µm | 62 µm | ||

| Z Control | 1 µm | 1 µm | ||

| Light Source | 405 nm UV LED | 385 nm UV LED | ||

| Material System | Open | Open | ||

| File Inputs | STL, SLC & Stomp | STL, SLC & Stomp | ||

| Software | Asiga Composer included | Asiga Composer included | ||

| Network Compatibility | Wifi and Ethernet | Wifi and Ethernet | ||

| Industry Sectors | Jewelry | Dental and Audiology | ||

| System Size | 26 × 38 × 37 cm | 26 × 38 × 37 cm | ||

| System Weight | 16.5 kg | 16.5 kg | ||

| Packaged Size | 41 × 50 × 48 cm | 41 × 50 × 48 cm | ||

| Power | 12 VDC 10A | 12 VDC 10A |

TRUSTED BY LABS ACROSS THE WORLD

See what others are saying about the Asiga Max:

ALEX PILET, HEAD OF ADVANCED TECHNOLOGIES

“After extensive internal testing of a variety of 3D printing systems, the Asiga MAX UV is clearly one of the best desktop 3D printers in terms of print quality and consistency for the tested dental indications."

Industries

Dental |

Audiology |

|---|---|

| • orthodontics • crown & bridge • dental models • custom trays • partial dentures • surgical guides |

• Ear Molds • Ear Shells • Silicone injection • Custom in ear audio • Production in ear audio |

Engineering |

Jewelry |

|---|---|

| • Product Development • Proof of concept • Usable prototypes • End use parts • Resin development • Metal casting capability of high and low temp alloys |

• Mold injection variance elimination • Quantity small parts • Large format parts • Direct high temp metal casting from grown waxes • Printed multi-part injection molds |